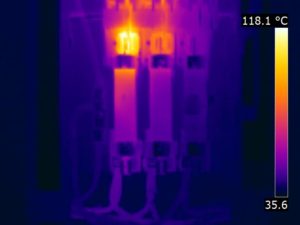

Infrared Inspection and Thermal Imaging Services for Electrical Power Equipment and Systems

Infrared Inspection, Thermal Imaging or Infrared Thermography is one of the most important aspect of preventive maintenance. Infrared Scanning is most commonly used to inspect electrical equipment because excess heat is usually the first sign of a problem.

Electrical Infrared Thermal Imaging Inspection is non-invasive non-intrusive maintenance.

Most electrical and mechanical equipment generate heat during normal operations. Usually, this heat is safely dissipated on its own. However, problems can develop when components generate excessive heat due to corrosion, loose connections, or overload. Infrared thermal imaging inspections identify these abnormal thermal rises in electrical and mechanical equipment before they cause an unplanned outage.

Many fires in the industry are directly related to faulty electrical components. Costly downtime is also often contributed to electrical failures and problems.

The principle behind an electrical fault is, as a connection deteriorates, the resistance to the flow of electrical energy increases. This electrical energy is transformed into thermal energy, which shows up as increased temperature.

Key Electrical Application Areas:

- Industrial Users: all process industries and manufacturing industries

- Commercial Users: warehouses, office buildings, hospitals, banks, schools, essentially all buildings that rely on electric power.

Benefits of Infrared Thermal Imaging:

- No equipment downtime

- Cost effective

- Prelude to preventive maintenance

- Locates problems not found during maintenance shutdowns

- Eliminates costly and unscheduled power shutdown

- Most facilities can be scanned in one day

- Non-intrusive and non-invasive service

- Detects overheating of electrical parts, componets wirings or conductors

- Locates problems not found during maintenance shutdowns

- Finds overloaded and unbalance load

Advantages of Using Thunder Testing:

- Electrical Testing and Maintenance Specialist

- Independent Contractor

- Performed according to NETA Maintenance Testing Standards

- Undertaken by professional and certified thermographer

- Certified Level 2 Infrared Thermographer

- Highly experienced thermographers with more than 15 years experience

- Full color, clear and concise thermographic reports

- Reports are delivered in printed hard copy and in Acrobat PDF file

What Electrical Equipment Should Be Inspected:

- Load Break Switches

- Power Transformers

- Main Circuit Breakers

- Distribution Panels

- Distribution Transformers

- Disconnect Switches

- Automatic Transfer Switches

- Electrical Panels

- Load Centers

- Motor Control Centers

- Motors

- Generators

- Batteries

- Terminal Connections

- Contactors

- Capacitor Banks

- Lightning Arresters

- Conductors

- Splices